Self-cleaning strainers, also known as self-cleaning filters, are a technological innovation in filtration systems that significantly enhance the efficiency of industrial filtration processes. They are designed to remove contaminants from liquids or gases in an automated and efficient manner.

Unlike traditional strainers that require manual cleaning and maintenance, self-cleaning strainers incorporate mechanisms that automatically clean the filtering elements, ensuring uninterrupted flow and optimal performance.

In this blog, we will learn about the principle of self-cleaning strainers.

The main component of self-cleaning filters

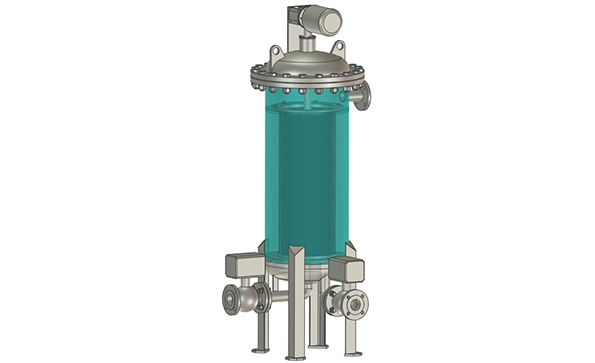

These auto self-cleaning strainers consist of several key components, including the housing or body where the fluid or gas flows through, inlet/outlet connections for easy integration into existing systems, and specially designed filtering elements such as screens or meshes. The main highlight of self-cleaning strainers is their ability to keep these filtering elements clean without human intervention.

How Do Automatic Self-Cleaning Strainers Work?

The working principle of automatic self-cleaning strainers involves trapping particles within the filtering element during the initial filtration stage. As contaminants accumulate on the surface of the filter media, different mechanisms are employed to remove them effectively. Commonly used cleaning mechanisms include backwashing systems, brushing systems, and pulse-jet systems.

▪ Backwash self-cleaning strainers

Backwashing systems use reverse flow techniques to dislodge debris from the filters. This can be achieved by either hydraulic methods where water or another liquid is forced back through the filter element or compressed air-driven systems where bursts of air create pressure differentials for effective cleaning.

▪ Scraper self-cleaning filter system

Brushing systems employ rotating brushes that physically sweep across the surface of the filter element to remove accumulated particles. These brushes can either rotate continuously or oscillate back and forth depending on design specifications.

Pulse-jet systems utilize blasts of compressed air directed at specific intervals onto the filter media surfaces. These rapid pulses create turbulence within the system, dislodging trapped particles from filters effectively while allowing continuous operation during cleaning cycles.

The above information explains the filtration principles of the three self-cleaning strainers. Do you comprehend them?

Reading More: