Tanks and vessels play a crucial role in storing, mixing, and processing various substances in industrial processing. However, the efficiency and effectiveness of these tanks and vessels rely heavily on their internal components.

Tank and vessel internals refer to the internal components of a tank or vessel that facilitate the storage, mixing, and processing of substances. Each internal component serves a specific purpose, ensuring the efficient operation of the tank or vessel.

We provide some common types of internals for tanks and vessels:

1. Header Lateral Screen

Header lateral screens are installed in tanks or vessels to distribute flow to optimize filtration and separation.

2. Ion Exchange Nozzle and Resin Trap

Our ion exchange nozzles and resin traps are manufactured with stainless steel corrosion-resistant and high-temperature resistant. The filters are installed in ion exchange resin containers for water petrol resin, and other mediums filtration.

3. Wedge Wire Cylinder

Our wedge wire cylinders are installed filter vessels to filter liquids, gases, and solids.

4. Support Grid

The support grids are used in towers for supporting structured packing. They allow free passage of gas and liquid. Our support grids are designed for drying towers, cooling towers, distillation columns, sulfuric acid absorption towers, and other tank applications.

The scallops are important components of reactor internals. They are positioned against the reactor wall through expander rings, and designed to collect or distribute flow.

6. Center Pipe/Inner Screen

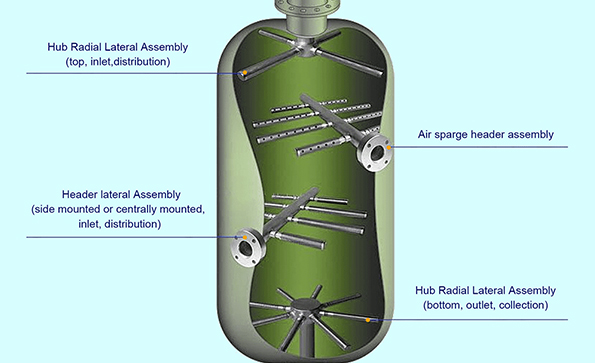

The center pipe is the central screening component in radial flow systems. It is usually installed inside vertical reactors and collects or distributes the flow.

1. Improved Efficiency: Tank and vessel internals optimize the performance of tanks and vessels, reducing processing time and increasing productivity.

2. Enhanced Safety: Internals help prevent accidents by ensuring proper mixing, temperature control, and level monitoring.

3. Increased Capacity: By optimizing tank and vessel performance, internals enable the processing of larger quantities, increasing production capacity.

4. Reduced Maintenance: Regular maintenance is simplified with easily accessible and replaceable internals.

5. Customization: Tank and vessel internals can be designed to meet specific processing requirements, ensuring optimal performance.