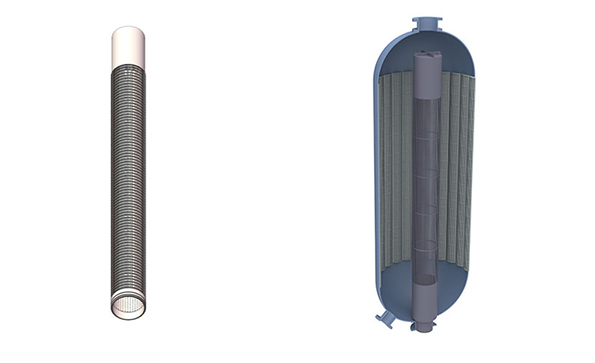

The reactor internal center pipe\inner screen is the central screening component in radial flow systems. It is designed to facilitate uniform flow distribution, maintain catalyst performance, and ensure operational safety under extreme conditions in petroleum refining.

In catalytic reforming reactors, the radial flow center pipe guides hydrocarbon feedstock evenly through the catalyst bed while withstanding high temperatures and pressures.

In the petroleum refining industry, catalytic reforming transforms low-octane hydrocarbons into high-octane reformates used in gasoline production.

Catalytic reforming processes, such as those used in producing reformates and hydrogen, rely heavily on reactor internals. The reactor's internal center pipe ensures that the high-pressure hydrocarbon feedstock is evenly distributed, optimizing the reforming reaction and enhancing product yield.

The center pipe is usually installed inside vertical radial flow reactors and collects or distributes the flow.

▪ Stainless steel material, corrosion resistance, and chemical wear.

▪ Wedge wire structure offers exceptional strength and resistance to collapse, buckling, or breaking.

▪ Plug-resistant slot design and high open area percentage.

▪ Optimized flow distribution and ensured uniform contact between feedstock and the catalyst.

▪ Custom design center pipes depending on radial flow reactor specifications.

Each petroleum refinery has unique operational demands. Custom center pipe designs cater to these specific requirements, ensuring:

▪ Seamless integration with existing reactor components.

▪ Enhanced performance in high-temperature and high-pressure environments.

▪ Improved compatibility with advanced catalyst support systems.

If you are looking for optimized solutions for catalytic reforming, consider partnering with experts in reactor internals to meet your refinery’s unique needs.

More Radial Flow Reactor Internals

| Wedge Wire Scallops | Wedge Wire Support Grids |

|  |