Basket filter is mainly composed of inlet and outlet pipes, filter cartridges, filter baskets, upper covers, sealing rings and fasteners. When the fluid enters the filter cartridge equipped with a filter screen of a certain specification, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is needed, open the drain valve, drain the remaining liquid, remove the upper cover, take out the filter basket, clean it, then reinstall it.

Product detail

A basket filter is a small piece of equipment to remove a small number of solid particles in a liquid, mainly composed of the main body, filter basket, flange, and fasteners. It can be installed on the pipeline to remove large solid impurities in the fluid. The machinery and equipment (including compressors, pumps, etc.) and instruments can work and operate normally, to stabilize the process and ensure safe production.

When the fluid enters the filter basket with a certain size of the filter, its impurities are blocked, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is required, open the sewage outlet at the bottom of the main body, drain the fluid, remove the flange cover, take out the filter basket, clean it and reload it. Therefore, it is extremely convenient to use and maintain.

Click here to learn about>>Features and Applications of Basket Filters

Technical parameter

| Inlet/Outlet | DN25~DN300 |

| Working pressure | 1MPa~6.4MPa |

| Working temp | -30℃~200℃ |

| Filtering precision | 10~300mesh |

| Flange | HG20592、HG20615、ASME B16.5 or customized |

| Housing material | Carbon steel, SS304, SS316, SS316 or customized |

| Basket material | SS304, SS316, SS316 or customized |

| Sealing material | Nitrile rubber, fluorine rubber, PTFE |

| Filtering media | 1.Weakly corrosive materials in chemical and petrochemical production, such as water, ammonia, oil, hydrocarbons, etc.2.Low-temperature materials in refrigeration, such as liquid methane, liquid ammonia, oxygen and various refrigerants3.Materials with hygienic requirements in the food or pharmaceutical industry, such as beer, beverages, dairy products, pharmaceuticals, etc. |

YUBO offers different styles of basket filters according to your industry.

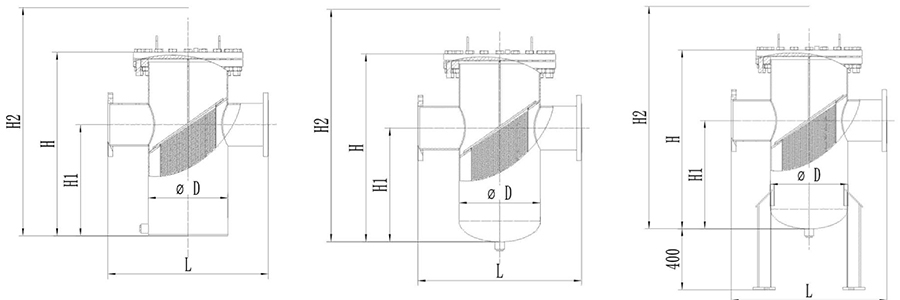

1. YZL series Basket Strainer

| Type | Import and export | D | H1 | H | L | H2(Maintenance space) | Sewage outlet |

| YZL50 | DN25~DN50 | 114 | 160 | 300 | 260 | 500 | DN10 |

| YZL65 | DN65 | 140 | 175 | 365 | 373 | 640 | DN15 |

| YZL80 | DN80 | 168 | 215 | 420 | 400 | 720 | DN15 |

| YZL100 | DN100 | 219 | 270 | 510 | 460 | 880 | DN20 |

| YZL125 | DN125 | 273 | 345 | 620 | 510 | 1080 | DN20 |

| YZL150 | DN150 | 325 | 410 | 725 | 560 | 1280 | DN25 |

| YZL200 | DN200 | 355 | 450 | 800 | 600 | 1400 | DN25 |

| YZL250 | DN250 | 406 | 495 | 895 | 670 | 1550 | DN25 |

| YZL300 | DN300 | 457 | 560 | 995 | 720 | 1750 | DN25 |

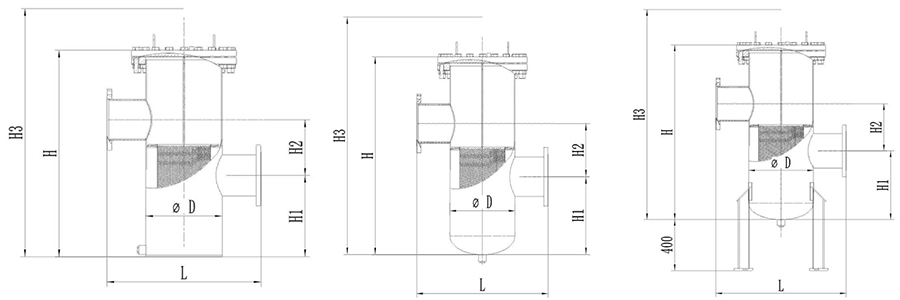

2. YXL series basket filter

| Type | Import and export | D | H1 | H2 | H | L | H3(Maintenance space) | Sewage outlet |

| YXL50 | DN25~DN50 | 114 | 160 | 110 | 340 | 260 | 600 | DN10 |

| YXL65 | DN65 | 140 | 200 | 130 | 555 | 460 | 980 | DN15 |

| YXL80 | DN80 | 168 | 200 | 130 | 555 | 460 | 980 | DN15 |

| YXL100 | DN100 | 219 | 250 | 175 | 690 | 520 | 1230 | DN20 |

| YXL125 | DN125 | 273 | 250 | 175 | 690 | 520 | 1230 | DN20 |

| YXL150 | DN150 | 325 | 285 | 210 | 800 | 575 | 1400 | DN25 |

| YXL200 | DN200 | 355 | 340 | 270 | 980 | 710 | 1710 | DN25 |

| YXL250 | DN250 | 406 | 395 | 335 | 1130 | 800 | 1950 | DN25 |

| YXL300 | DN300 | 457 | 445 | 375 | 1275 | 870 | 2220 | DN25 |

How does it work

Basket filter is mainly composed of inlet and outlet pipes, filter cartridges, filter baskets, upper covers, sealing rings and fasteners. When the fluid enters the filter cartridge equipped with a filter screen of a certain specification, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is needed, open the drain valve, drain the remaining liquid, remove the upper cover, take out the filter basket, clean it, then reinstall it.

Application

Basket filter is an indispensable device on the pipeline of conveying medium. It is usually installed at the inlet of pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to filter impurities in the medium to protect the valve and equipment. Basket filter is widely used in the industries of chemical, petrochemical, petroleum, paper, mining, electric power, liquefied gas, food, pharmaceuticals, water supply and drainage, municipal project, mechanical equipment, electronics, construction and other fields.

How to select the proper filter

1. Inlet and outlet diameter: in principle, the inlet and outlet diameter of the filter shall not be smaller than the inlet diameter of the matching pump, and it is generally the same as the inlet pipe diameter.

2. Nominal pressure: pressure level of the filter shall be determined according to the highest pressure that may occur in the filter pipeline.

3. Selection of aperture: key factor to be considered is the particle size of impurities to be intercepted, which is determined according to the processing requirements of the medium. Please ask us the info of the particle size that can be intercepted by filters.

4. Material: material of the filter is generally the same as the material of the connected process pipeline. Different material such as stainless steel, carbon steek, or low alloy steel to be chosen according to your working conditions.

5. Opening area: opening area of the filter basket is 2-3 times larger than the area of the inlet pipe, and the pressure difference is 0.05-0.15MPa.

How to install

1. Before installation, please make sure the fastening of the screws and the filter is clean. The basket filter is generally installed horizontally. The direction of the inlet and outlet should be consistent with the direction of the arrow on the valve body. Install before the pipe inlet ( Before the pump). During installing, please pay attention to the sign of flow direction.

2. The core part of filtering is the cylindrical screen. The screen is made of wire mesh or wedge wire. The screen is wearing part and it needs to be regular maintained.

3. After working for a period of time, certain impurities can be precipitated in the filter basket. Pressure drop will increase and the flow rate will decrease consequently. Therefore, the impurities in the filter basket must be removed in time.

4. Filter basket shall be protected from deformation or damage when cleaning impurities, otherwise poor performance of filtering will occur.