In the high-stakes world of petroleum refining, the quality of reactor internals plays a critical role in optimizing performance, maximizing catalyst efficiency, and ensuring long-term plant reliability.

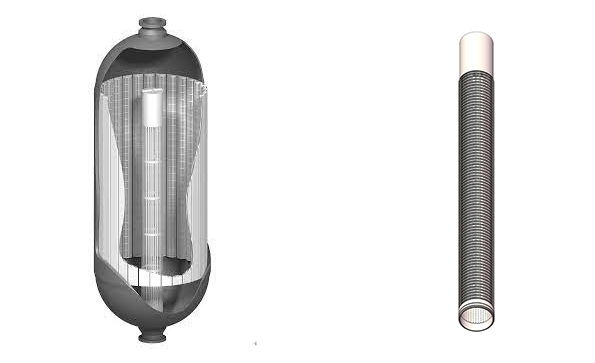

Among these internals, the center pipe - especially with wedge wire technology - is vital to the smooth operation of fixed-bed and radial flow reactors used in hydrocracking, hydroprocessing, and catalytic reforming.

A wedge wire center pipe is the main structural and functional element within a reactor's catalyst bed. It facilitates uniform flow distribution - either gas or liquid - through the catalyst bed and supports catalyst retention, especially in downflow or radial flow reactor systems.

Constructed from stainless steel or other corrosion-resistant materials, center pipes with wedge wire screens ensure high mechanical strength, resistance to fouling, and excellent flow characteristics.

As demand grows across global markets, the Russian refining sector is increasingly seeking durable, efficient, and cost-effective solutions. Wedge wire reactor internals, particularly center pipes, are answering this call.

The wedge wire screen - also known as Vee wire or Johnson screen - is crafted by welding V-shaped wires onto support rods. This design creates a slot-shaped opening that offers several operational advantages:

• Precise slot openings to prevent catalyst leakage

• Non-clogging surface is ideal for continuous operation

• High mechanical strength under extreme temperatures and pressures

• Customizable dimensions to fit various reactor configurations

• Material Options: 304L, 316L, Duplex stainless steel - suited for aggressive refining environment

• Flow Optimization: Engineered for even distribution across the catalyst bed

• Maintenance-Free: Anti-clogging design reduces downtime and operational costs

• Custom Fabrication: Tailored to reactor dimensions and specifications in oil & gas facilities

• Compatibility: Ideal for hydrocracking, hydrodesulfurization, and other refining processes

These features make wedge wire reactor center pipes a preferred choice for refinery operators in Russia, where heavy crude processing demands robust internal components.

Our wedge wire internals are widely used in the following reactor types:

Fixed-bed reactors

Radial flow reactors

Hydrotreating units

Hydrocracking reactors

Catalytic reformers

Their integration helps maximize throughput, minimize pressure drops, and ensure uniform catalyst utilization - all critical for modern refining operations.

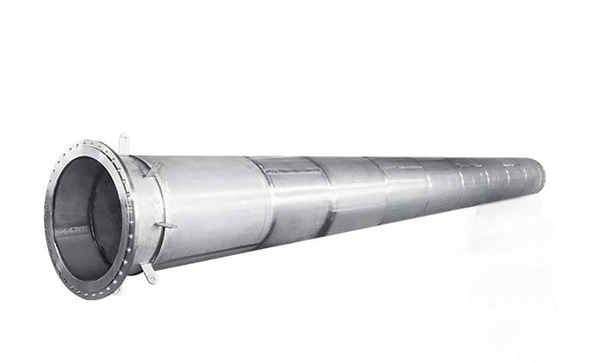

We offer various wedge wire reactor internals designed for Russian petroleum refining plants, including Vee wire scallops, center pipes, headers, and laterals.