Strainers remove debris and solid particles from the flow to protect equipment in fluid handling systems. Two of the most commonly used filtration devices are temporary strainers and permanent strainers. Although they serve the same basic function - filtering contaminants from pipelines, the difference lies in their design, usage, lifespan, and maintenance.

A temporary strainer, often referred to as a start-up strainer, is designed for short-term use during the commissioning phase of a piping system. It is usually installed to trap construction debris, welding slag, rust, or other contaminants that may be present when the system is first activated.

Types of Temporary Strainers:

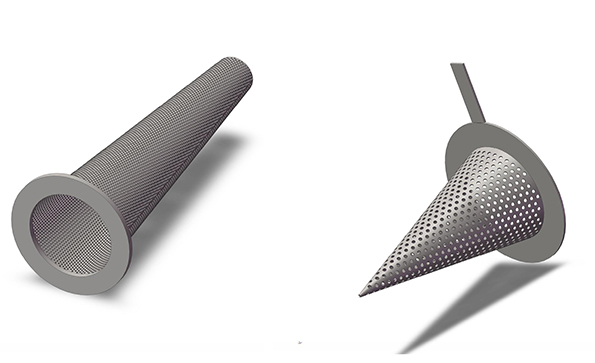

• Temporary Cone Strainer: Shaped like a cone and installed inside flanged connections.

• Basket Strainer (temporary type): Cylindrical or flat and used where more surface area is needed.•

• Tee Strainer (temporary type): Installed in a straight run of pipe and useful for compact spaces.

Click here to learn more:

Temporary Strainer - Cone, Basket, Flat Type

Witches Hat Strainer Flow Direction

Temporary strainers are typically made from stainless steel wire mesh or perforated plates and are designed to be removed once the system is clean.

A permanent strainer is built for continuous use throughout the system's life. These strainers are more robust, offer long-term flow protection, and are often part of the system’s permanent infrastructure.

Types of Permanent Strainers:

• Y-Strainer: A Y-shaped body suitable for horizontal or vertical installations.

• Basket Strainer (permanent type): Offers a large filtration area and is commonly used in larger piping systems.

• Tee Strainer (permanent type): Installed inline and used where space is limited.

Permanent strainers typically come with a removable strainer element that can be cleaned and reused, making them more cost-effective over time.

Temporary vs Permanent Strainer: A Side-by-Side Comparison

| Feature | Temporary Strainer | Permanent Strainer |

| Usage | Start-up or short-term filtration | Continuous, long-term filtration |

| Installation | Temporary insertion during start-up | Permanently installed in the pipeline |

| Removal | Removed after initial cleaning cycle | Stays in the system, element is cleaned |

| Cost | Lower upfront cost | Higher initial investment |

| Maintenance | Often disposed of after use | Requires periodic cleaning or servicing |

| Mesh Size | Varies depending on start-up needs | Customizable for system requirements |

| Materials | Lightweight metals or mesh | Stainless steel or cast construction |

| Common Applications | New installations, system flushing | Process lines, HVAC, water treatment |

Temporary strainers are ideal when:

• Commissioning a new pipeline system.

• Performing maintenance or flushing operations.

• Short-term filtration is required before installing a permanent solution.

They help prevent damage to pumps, valves, and flow meters during the early stages of operation by catching debris that could cause costly failures.

Permanent strainers are best for:

• Continuous operation in industrial, HVAC, or water treatment systems.

• Applications where long-term equipment protection is needed.

• Situations requiring consistent filtration performance and easy maintenance.

For example, Y-strainers and basket strainers are widely used in chemical processing plants, cooling water systems, and oil and gas pipelines due to their durability and filtration efficiency.

• Flow rate and pressure drop: Ensure the selected strainer does not cause excessive pressure loss.

• Filtration efficiency: Choose the appropriate mesh size or perforation to suit your medium.

• Installation orientation: Some strainers are better for horizontal piping; others suit vertical lines.

• Material compatibility: Use stainless steel for corrosive environments or potable water.

Understanding the difference between temporary and permanent strainers is critical for designing efficient and reliable fluid systems. While temporary strainers serve as an essential tool during start-up and commissioning, permanent strainers ensure ongoing protection and filtration in pipelines across various industries.

Contact us or leave a message below the website to get more information about temporary filters, wedge wire screens, and strainers!