✔ Continuous Operation

✔ Minimal ,aintenance

✔ High Filtration Performance

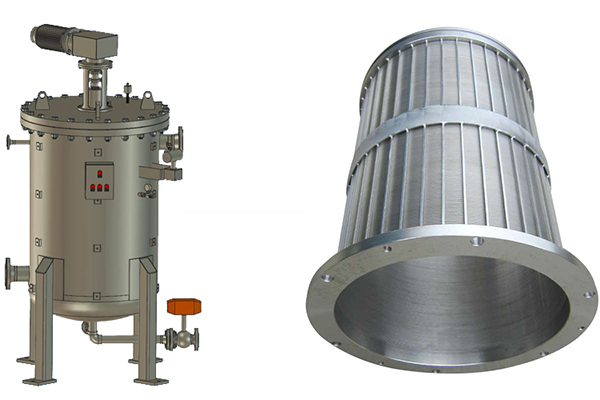

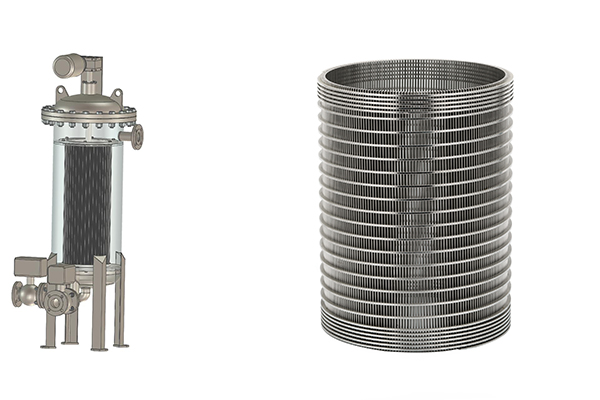

A self-cleaning filter is an automated system designed to remove solid particles from liquids or gases without manual intervention. The wedge wire screen cylinderserves as the primary filtration element, featuring V-shaped stainless steel wires that allow for precise and efficient separation of contaminants.

The self-cleaning process typically involves:

▪ Filtration Phase: Fluid passes through the wedge wire cylindrical screen, trapping contaminants while allowing clean liquid to flow through.

▪ Cleaning Phase: An automatic backwash mechanism removes accumulated debris from the screen without halting operations.

▪ Continuous Operation: Unlike traditional filters that require frequent replacement, self-cleaning filters ensure an uninterrupted process with minimal downtime.

Implementing a self-cleaning filtration system with a wedge wire screen offers numerous advantages for industrial applications:

1. Enhanced Efficiency

The automatic self-cleaning filter reduces clogging and maintains a consistent flow rate, improving overall system performance.

2. Reduced Maintenance and Downtime

With a continuous self-cleaning filter, manual cleaning and frequent filter replacement are minimized, reducing labor costs and production disruptions.

3. Superior Filtration Performance

The stainless steel wedge wire filter is designed for high-precision filtration, making it ideal for separating solid particles from liquids, even in high-viscosity fluids.

4. Durability and Longevity

The wedge wire mesh filter is constructed from stainless steel, providing corrosion resistance and long-term reliability in demanding industrial environments.

5. Eco-Friendly and Cost-Effective

Self-cleaning filters support sustainable operations and lower operational costs.

▪ Water Treatment: Removing sediments, algae, and other impurities from municipal and industrial water systems.

▪ Food and Beverage: Ensuring hygiene and product quality by filtering liquids like juices, beer, and dairy products.

▪ Chemical Processing: Preventing contamination in chemical solutions and improving process efficiency.

▪ Oil and Gas: Filtering impurities from crude oil, lubricants, and refinery byproducts.

▪ Power Plants: Protecting cooling water systems from debris and sediment accumulation.

When selecting a self-cleaning filter with a wedge wire screen cylinder, consider factors such as:

▪ Filtration rating: Choose a screen with the appropriate micron size to capture desired contaminants.

▪ Flow rate: Ensure the filter can handle the required capacity without causing pressure drops.

▪ Material composition: Opt for stainless steel automatic filtration systems for corrosion resistance and durability.

▪ Backwash mechanism: Select a system with an efficient and reliable automatic backwash filter function.

A self-cleaning filter with a wedge wire screen cylinder can operate continuously, reduce downtime, and provide high-precision filtration, making it a preferred choice across various applications.