A self-cleaning filter housing - YGN is suitable for the filtration of water and various viscous liquids.

YGN series self-cleaning filter automatically removes particles and impurities from the inner surface of the screen through the scraper inside of the screen drum, while keeping the filtration process uninterrupted. YGN series self-cleaning filter solves the filtration problems you may encounter in production with excellent filtration performance.

Product Brief Description

Self-cleaning filters are used to protect pipelines and various downstream equipment. Without adequate filtration, the scale will build up in the channel and increase the energy required to pump the water.

YGN series self-cleaning filter automatically removes particles and impurities from the inner surface of the screen through the scraper inside of the screen drum, while keeping the filtration process uninterrupted. YGN series self-cleaning filter solves the filtration problems you may encounter in production with excellent filtration performance.

YGN self-cleaning filter is suitable for the filtration of water and various viscous liquids

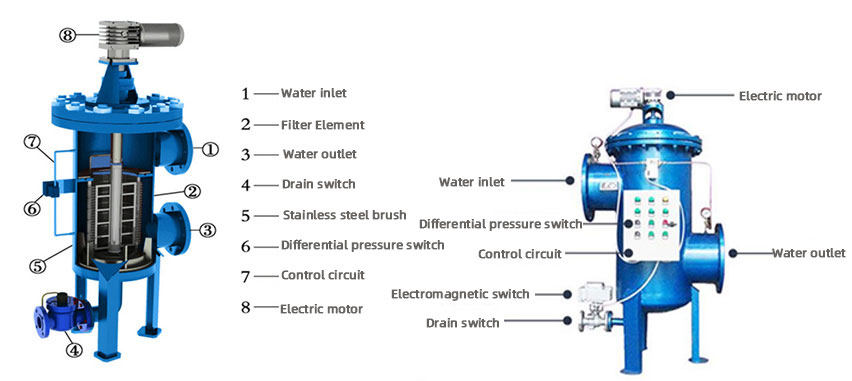

How does an electric inner scraper self-cleaning filter work?

Click here to learn about>> Working Principle of Electric Inner Scraper Self-Cleaning Filter

The scraper filter is divided into:

1. Scraper self-cleaning filter housing-YGY;

2. Scraper self-cleaning filter housing-YGN;

3. Scraper self-cleaning filter housing-YGP;

Product Specification Parameters

| Applicable liquid | Water and viscous liquids (<800,000 cps), impurities <1000 ppm |

| Filter precision | 30-1500μM |

| Standard Design Pressure Rating | 1.0MPa, higher pressure can be customized |

| Design temperature | 0-200°C (depending on seal) |

| Single filter area | 0.14 M2-1.45 m2 |

| Cleaning differential pressure | 0.05MPa |

| Differential pressure transmitter | Pressure differential transmitter or pressure differential switch |

| Reduction motor | 550W, three-phase,380V, protection grade IP55; worm gear reducer |

| Inlet/outlet connection standard | Flange HG20592-2009 (standard design), HG20615-2009 (compatible with ANSI B16.5), etc. |

| Filter element type material | V-shaped wedge mesh, material 304/316 L/2205/titanium, etc. |

| Material of shell connecting liquid | 304/316L/CS |

| Scraper material | Copper/Alloy Steel/PTFE |

| Shell sealing material | NBR Nitrile (Standard)/ Viton (FKM) Viton |

| Blowdown valve | Pneumatic (electric) ball valve, protection grade IP55 |

| Utility Supply Requirements | 380V AC,0.4-0.6MPa clean dry compressed air |

Main parameters and dimensions of equipment

| TYPE | YGN -273 | YGN -325 | YGN -426 | YGN -478 | YGN -530 | YGN -630 | YGN -720 | YGN -820 | YGN -920 | YGN -1020 |

| Exit and entry diameter(mm) | 50 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| Flow (m³/h) | 15 | 40 | 65 | 140 | 250 | 390 | 560 | 750 | 1010 | 1300 |

| D (mm) | 273 | 325 | 426 | 478 | 530 | 630 | 720 | 820 | 920 | 1020 |

| H1 (mm) | 950 | 1070 | 1275 | 1360 | 1450 | 1600 | 1900 | 1980 | 2200 | 2400 |

| H2 (mm) | 450 | 570 | 750 | 800 | 880 | 960 | 1020 | 1050 | 1130 | 1350 |

| H3 (mm) | 150 | 150 | 200 | 240 | 300 | 300 | 350 | 400 | 400 | 450 |

| H4 (mm) | 1450 | 1600 | 1870 | 1980 | 2200 | 2460 | 2550 | 2760 | 2840 | 3120 |

| Filter area(m²) | 0.25 | 0.35 | 0.66 | 0.84 | 1 | 1.2 | 1.5 | 1.8 | 2 | 2.3 |

| Drain valve(mm) | 25 | 25 | 50 | 50 | 50 | 80 | 80 | 80 | 80 | 80 |

| Amount of cleaning water(L) | 80 | 80 | 150 | 150 | 150 | 350 | 450 | 600 | 800 | 1000 |

| Motor Power(KW) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Tip: | The flow rate in the table is measured according to the economic flow rate when the filtration precision is 100μm. | |||||||||

Product Advantage

■ Fully automatic operation,24-hour continuous online filtration, end the heavy filter element replacement and cleaning

■ Don't generate disposable filter consumables, without manual cleaning, save cost

■ Excellent scraping effect with metal flake scraper, which can significantly improve the impurity removal capacity and avoid crushing impurities.

■ Top quality V-SLOT filter, precise gap, extremely smooth surface, easy to scrape, high strength, long life

■ Very small filter pressure loss, stable flow, energy-saving, conducive to continuous process stability

■ Add backwash function to assist in cleaning filter elements

■ Closed filtration to prevent leakage of hazardous materials, which is conducive to safe production

■ High concentration of impurities in discharged waste liquid and recoverable to avoid loss of high-value materials

■ Multiple module combinations and optional automation modes for a wide range of filtering applications

■ Extremely high reliability and long service life with standard Gearmotor of the internationally renowned brand

■ Standard upper cover auxiliary lifting device, one person can open and close the filter

Application

Application: Kerosene, polymer, water, fermentation broth, protein, grease, wet end additive, calcium carbonate, starch, filler, adhesive, ink, pigment, coating, resin, rubber, ethanol, chocolate, candy, high-temperature oil, edible oil, honey, fruit juice, coolant, diesel, citric acid, soap, sorbitol, etc.