Candle filter is a filter with an advanced filter cloth and a unique control system. Candle filters are an approach for removing fine particles.

Candle filter is suitable for: high content and fine particles, corrosive, toxic and odorous, and other harsh environments, automatic filtration.

Candle filter is a filter with an advanced filter cloth and a unique control system. Candle filters are an approach for removing fine particles.

Candle filter is suitable for: high content and fine particles, corrosive, toxic and odorous, and other harsh environments, automatic filtration.

Candle Filters are also used for thickening to produce a concentrated flowable slurry by partial removal of the liquid phase as filtrate. This mode of operation is possible since Candle Filters may operate on very short cycle times taking advantage of the high filtration rates whilst the cakes are still thin. One of the features of Candle Filters, when used for thickening, is their clear filtrate since gravity Thickeners, in analogy, produce overflows which always contain a certain amount of fine suspended solids.

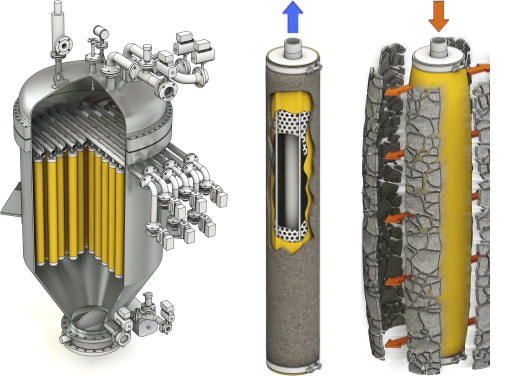

Another feature of Candle Filters is the cylindrical shape of the elements that retain the formed cake.

Candle Filters are very well suited for handling flammable, toxic, and corrosive materials since they are autoclaved and designed for hazardous environments when high pressure and safe operation are required.

How Does A Candle Filter Work? (Click here to learn about)

The Candle Filter consists of three major components:

The vessel

The filtering elements

The cake discharge mechanism

Candle filters provide for thin-cake pressure filtration, cake washing, drying, slurry, and automatic discharge as well as heel filtration in an enclosed pressure vessel.

Candle filters require frequent maintenance. Because of particle build-up and the resulting reduced flow rates, filters must be cleaned with a soft brush and clean water every 2 weeks.

The service life of candle filters varies, but they should be replaced every 6-12 months.

Advantages

1) Completely airtight filtration, no leakage, no environmental pollution

2) The structure of the filter element adopts a duplex structure, and the flow rate is large

3) Pulse gas is used for back blowing and slag discharge, and the filter cake is easy to fall off, suitable for viscous materials

4) The operation process can be fully automated

Disadvantages

1)High headroom is required for dismantling the filtering elements.

2)The emptying of the vessel in between cake filtration, washing and drying requires close monitoring of the pressure inside the vessel to ensure that the cake holds on to the candles.

Candle Filters are best selected in the following instances:

1. When minimum floor space for large filtration areas is required.

2. When the liquids are volatile and may not be subjected to vacuum.

3. When there is a risk of environmental hazard from toxic, flammable, or volatile cakes specially secured discharge mechanisms may be incorporated.

4. When high filtrate clarity is required for polishing applications.

5. When handling saturated brines that require elevated temperatures the tank may be steam jacketed.

6. When the cake may be discharged either dry or as a thickened slurry.

You can directly leave your industry needs and contact information, our engineering designers will provide you with the most suitable filters and filtration scheme for you.