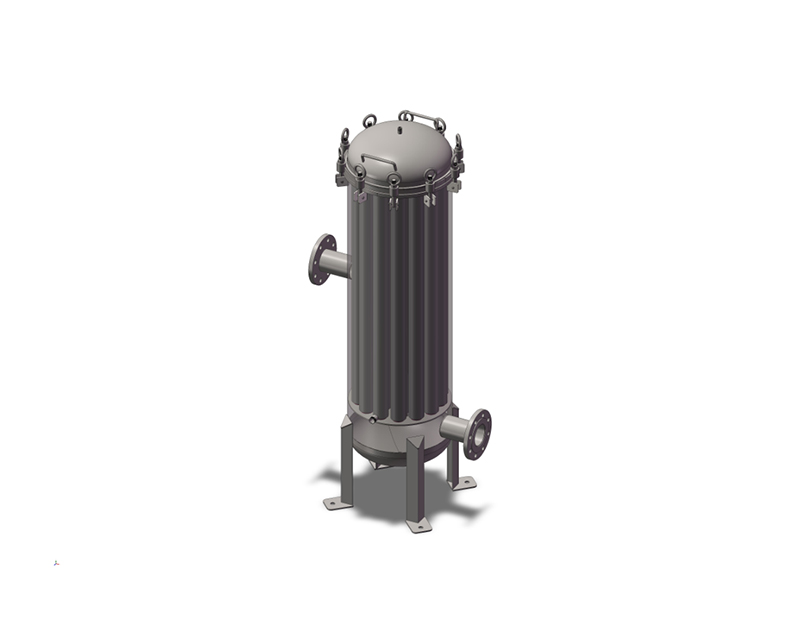

The filter element type liquid filter is a new type of multifunctional filter, which consists of two parts: the stainless steel filter housing and the filter element. It has been widely used in water, oil, paint and other liquid purification and solid-liquid separation in machinery, metallurgy, chemical, textile, printing and dyeing, electroplating, medicine, food and other industries.

YUBO can provide custom cartridge filters in different sizes to meet specific flow and filtration requirements.

Cartridge filters are used in a variety of industries to meet a range of filtration requirements, handling various flow rates. Industrial cartridge filters provide high levels of filtration for many applications, including municipal water filtration, boiler water supply, machine tool coolants, chemicals, and custom facility water filtration processes.

Click here to learn about:

Benefits and Applications of Cartridge Filter

What Does Cartridge Filter Remove?

Features of cartridge filters:

1. Provides lower total cost of filtration operations and resists contaminant unloading even at high differential pressures.

2. Melt-bonded exterior ensures no media migration and helps prevent premature surface blinding.

3. Offers special coating options for corrosion resistance.

4. Features easily openable lid options without the need for any special tools.

5. Achieves a filtration degree down to 0.2 microns.

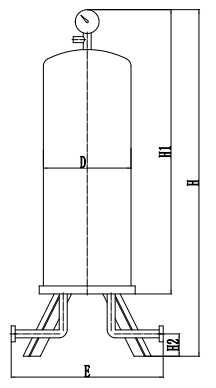

Product Model

| Type | theoretical flow | filter cartridge | import and export | Dimensions | ||||||

| m³/h | number | length mm | outer diameter mm | H mm | H1 mm | H2 mm | D mm | E mm | pressure | |

| YTQ100-10 | 0.3-0.5 | 1 | 10" | 25 | 600 | 400 | 80 | 100 | 220 | ≤0.6Mpa |

| YTQ100-20 | 0.5-1 | 20" | 25 | 800 | 600 | |||||

| YTQ100-30 | 1-1.5 | 30" | 25 | 1050 | 900 | |||||

| YTQ200-10 | 1-1.5 | 3 | 10" | 32 | 650 | 450 | 120 | 200 | 320 | |

| YTQ200-20 | 1.5-3 | 20" | 32 | 950 | 650 | |||||

| YTQ200-30 | 2.5-4.5 | 30" | 34 | 1150 | 950 | |||||

| YTQ220-10 | 1.5-2.5 | 5 | 10" | 32 | 650 | 450 | 120 | 220 | 350 | |

| YTQ220-20 | 3-5 | 20" | 32 | 950 | 650 | |||||

| YTQ220-30 | 4.5-7.5 | 30" | 38 | 1150 | 950 | |||||

| YTQ250-10 | 5-7 | 7 | 10" | 38 | 950 | 650 | 150 | 250 | 400 | |

| YTQ250-20 | 6-10 | 20" | 48 | 1150 | 950 | |||||

| YTQ250-30 | 8-14 | 30" | 48 | 1450 | 1200 | |||||

| YTQ300-20 | 6-8 | 9 | 20" | 48 | 1000 | 700 | 150 | 300 | 450 | |

| YTQ300-30 | 8-12 | 30" | 48 | 1250 | 950 | |||||

| YTQ300-40 | 12-15 | 40" | 48 | 1400 | 1200 | |||||

| YTQ350-20 | 6-12 | 12 | 20" | 48 | 1100 | 800 | 200 | 350 | 500 | |

| YTQ350-30 | 12-18 | 30" | 57 | 1350 | 1050 | |||||

| YTQ350-40 | 16-24 | 40" | 57 | 1600 | 1300 | |||||

| YTQ400-20 | 8-16 | 15 | 20" | 76 | 1100 | 800 | 200 | 400 | 550 | |

| YTQ400-30 | 18-25 | 30" | 76 | 1350 | 1050 | |||||

| YTQ400-40 | 20-30 | 40" | 76 | 1300 | 1300 | |||||

| Note 1. Filter element interface forms: M20/M30, 222 (plug-in type), 226 (snap-in type), flat pressure port, threaded port, etc. Special interfaces can be customized. 2. Import and export connection forms: quick installation, thread, flange, etc. 3. Pressure gauge (optional). | ||||||||||

Product Principle

The filter element type liquid filter is a new type of multifunctional filter, which consists of two parts: the filter housing and the filter element. It has been widely used in water, oil, paint, and other liquid purification and solid-liquid separation in machinery, metallurgy, chemical, textile, printing and dyeing, electroplating, medicine, food, and other industries.

Product Category

Filter element filters can be divided into the following types according to the commonly used filter elements:

1). Filter with PP filter element

PP filter element is also called PP melt blown filter element. The melt-blown filter element is made of polypropylene ultra-fine fiber thermally entangled. The fibers randomly form a three-dimensional microporous structure in space, and the dimensional pore size is distributed in a gradient along the flow direction of the filtrate. It integrates surface, deep, and fine filtration to trap impurities of different particle sizes. The accuracy range of the filter element is 0.5-100μm, and its flux is more than 1.5 times that of the peak room filter element of the same accuracy. Different types of end cap connectors can be configured to meet the needs of various engineering installations.

2). Filter with wire wound filter element

It is refined by finely winding textile fiber yarn with good filtering performance on a porous skeleton. Its yarn materials include polypropylene fiber, acrylic fiber, absorbent cotton fiber, etc. By controlling the tightness and thinness of the yarn during winding, filter elements with different precision can be made, which can effectively remove suspended solids and particulate impurities in various liquids, and have a high purification effect on various liquids.

3). Filter with pleated filter element

The pleated filter element is a precision filter device made of Polypropylene thermal spray fiber membrane, Nylonb, PTEE microporous filter membrane, etc. as the filter medium. It has the advantages of small volume, large filter area, and high precision. Filter accuracy can range from 0.1μm to 60μm. The filter element end cover sealing and the overall structure connection are all hot-melt bonding. There are three kinds of filter element joints commonly used in the world: 222 joints, 226 joints and flat joints. The products have undergone strict and complete testing before leaving the factory to ensure the stable performance of the products.

4). Filter with activated carbon filter element

There are two categories of activated carbon filter products:

Compressed activated carbon filter element, bulk activated carbon filter element.

A. The compressed activated carbon filter element uses coal-based activated carbon and coconut shell activated carbon with high adsorption value as the filter material, and is sintered and compressed with a food-grade binder. The inside and outside of the compressed activated carbon filter element are respectively wrapped with a layer of non-woven fabric with filtering effect to ensure that the carbon core itself does not drop carbon powder. The two ends of the carbon core are equipped with soft nitrile rubber gaskets, so that the carbon core is installed in the filter cartridge with good tightness.

B. Bulk activated carbon filter element put the required activated carbon particles into a special plastic tank, and be used welding equipment to weld the end caps to the two ends of the shell. The two ends of the tank are respectively put into non-woven filter sheets for filtering to ensure that the carbon core will not drop carbon powder and black water during use. According to the needs of customers, the tank end cover can be made into different types of connection ports. Interface methods include flat pressure type, pipeline type (models: 4042, 4044, 4046, etc.).

5). Filter with double section filter element

Previous section: Polypropylene melt blown filter element with a precision of 5μm

Next section: Granular activated carbon filter element with built-in activated carbon 170g

Material: ABS, PP

Length: 250mm Outer diameter: 70mm Flux: 8L/S Total flux: 6-8T

Activated carbon index: strength>90; iodine value (mg/g)>950; methylene blue value (mg/g)>120

Resin is a porous, insoluble material. There are millions of tiny plastic balls (beads) in the resin filter element of the water softener, all of which contain many negative charge exchange positions that absorb positive ions. When the resin is in the nascent state, these charge exchange sites are occupied by positively charged sodium ions.

When calcium and magnesium pass through the resin storage tank, they come into contact with the resin beads and replace the sodium ions from the exchange position. The resin preferentially binds cations with a stronger charge, and calcium and magnesium ions have a stronger charge than sodium ions. Replace the sodium cations and then pass down the resin "bed”, out of the water softener, so that the water softener sends out "soft" water. Finally, all resin exchange positions are occupied by calcium and magnesium, and work can no longer be performed.

7). Filter with RO reverse osmosis filter element

Filter element with RO reverse osmosis membrane: Reverse osmosis technology: the original text of reverse osmosis is REVERSE OSMOSIS, which is a collection of scientists from the United States National Space Agency, with government support, spent billions of dollars, after years of research. The principle of reverse osmosis is to apply a pressure greater than the natural osmotic pressure on the raw water side, so that water molecules reverse osmosis from the higher concentration side to the lower concentration side.

Since the pore size of the reverse osmosis membrane is much smaller than hundreds of times or even thousands of times that of case viruses and bacteria, all kinds of viruses, bacteria, heavy metals, solid soluble matter, polluting organic matter, calcium and magnesium ions, etc. cannot pass through the reverse osmosis membrane. , So as to achieve the purpose of water softening and purification.

8). Filter with stainless steel filter

Features of stainless steel filter element:

A. Good filtration performance, uniform surface filtration performance for 2-200um filtration particle size

B. Good corrosion resistance, heat resistance, pressure resistance and wear resistance;

C. The stainless steel filter element has uniform and precise filtration accuracy;

D. The flow rate per unit area of the stainless steel filter element is large;

F. The stainless steel filter element is suitable for low temperature and high temperature environment; it can be used again after cleaning, no need to replace.

Contact us

For advice and custom cartridge filters or filtration solutions please contact us directly for a quote.

WhatsApp:86 13653285589, Email: sales@yubofilter.com

Our team of filter experts is available 24/7.

We have specialized in industrial filtration for more than 10 years.