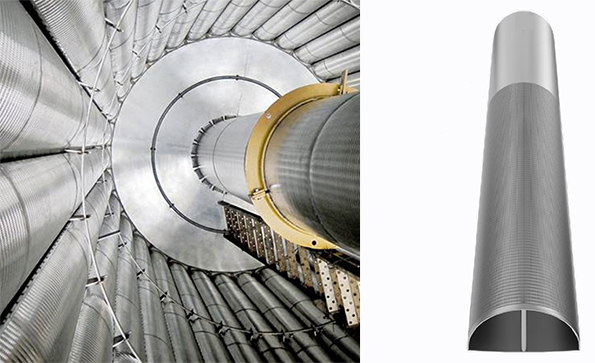

A Johnson screen scallop is a wedge wire screen segment designed as a reactor internal to support catalyst beds and facilitate optimal radial or axial flow distribution in fixed-bed or downflow reactor systems. Its curved, scallop-like form allows it to line the inner wall of the pressure vessel, creating flow channels while maintaining catalyst containment.

These wedge wire scallops are often installed alongside hub and header lateral assemblies, ensuring uniform flow and minimizing channeling or hot spots during operation. Their precision-engineered V wire profiles deliver exceptional strength, anti-clogging capability, and resistance to fouling under extreme pressure and temperature conditions.

The Johnson screen scallop has emerged as a trusted and indispensable internal part of fixed-bed reactors, particularly in hydrocracking and hydrotreating units.

Johnson scallop screens are widely used in:

Hydrocracking reactors

Hydrotreating units

Fixed-bed reactors

Catalytic reforming reactors

FCC unit reactors

Hydrogenation and dehydrogenation processes

Their role is to support catalyst material, enable consistent flow distribution, and protect other internal components, such as distributors, collectors, and outlet baskets.

YUBO Filtration is a professional Johnson screen scallop manufacturer, offering custom design services.

1. Tailored Solutions for Complex Reactor Designs

Every reactor has its process requirements. We can design custom scallop screen segments that match the vessel’s curvature, flow direction, and mechanical stress conditions.

2. High-Performance Wedge Wire Construction

Using wedge wire (V wire) profiles allows scallop screens to maintain precise slot openings—typically between 0.05 mm and 2 mm—ensuring smooth fluid flow while retaining catalyst particles. The non-clogging surface reduces downtime due to fouling and enhances the lifespan of catalyst beds.

3. Superior Resistance to Corrosion and Pressure

Refinery environments are aggressive, with high temperatures, pressures, and chemical exposure. A well-manufactured stainless steel scallop screen offers exceptional durability, corrosion resistance, and thermal stability, making it ideal for high-pressure reactor applications.

Contact Information

E-mail: sales@yubofilter.com

WhatsApp: 86 13653285589

• Material Options: SS304, SS316L, Duplex, Hastelloy, Inconel

• Slot Sizes: Customizable to process flow and catalyst requirements

• Precision Fabrication: Each scallop segment is engineered to exact vessel geometry

• Modular Design: Allows for easy installation and replacement

• High Flow Efficiency: Optimized for maximum flow and minimal pressure drop

Petroleum Refineries

Petrochemical Plants

Hydrogenation Facilities

Gas-to-Liquids (GTL) Units

Chemical Processing Plants

Why Engineers and Procurement Managers Trust Us

✔ OEM-Grade Manufacturing

✔ Engineering & Design Support

✔ Fast Global Delivery

✔ Custom Builds for Legacy Reactors

✔ Proven Track Record in Hydrocracking and Hydrotreating Reactors

We don't just manufacture; we solve engineering problems. Our Johnson scallop screens are used by some of the world's top EPCs and refineries for revamp projects, turnaround maintenance, and new reactor installations.

Contact us today to discuss your reactor internals project or request a quote for Johnson screen scallop manufacturing.