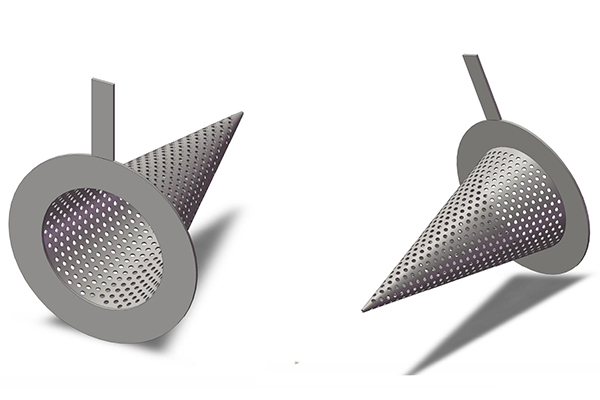

A conical witch hat filter, also known as a cone strainer, is a temporary or permanent inline strainer made of durable materials like stainless steel 304 or 316. It is typically installed in piping systems to catch solid particles before they reach critical equipment. These filters are known for their high flow capacity, excellent pressure resistance, and ease of maintenance.

The cone design allows for a larger filtration area in a compact footprint, which translates to reduced pressure drop and increased efficiency. Available in a variety of mesh sizes and perforation patterns, these filters can be customized for a wide range of industrial applications.

When commissioning or maintaining industrial pipelines, conical witch hat filters are essential for safeguarding pumps, valves, and downstream equipment.

These stainless steel cone-shaped strainers are a reliable choice across various industries, including oil and gas, chemical processing, food, beverage, and water treatment.

1. Superior Filtration Efficiency

The uniquely tapered design maximizes surface area, ensuring effective removal of medium-to-large debris while minimizing clogging.

Fine wire mesh or perforated variants provide precise solid capture, ideal for sanitary and high-purity systems.

2. Rugged & Low-Maintenance Design

Crafted from stainless steel 304 or 316 (with options such as 316L, carbon, or alloy steels), these conical filters withstand high pressures, temperatures, and corrosive media.

Reusable and straightforward to clean, remove, flush, or chemically wash, and redeploy in minutes.

3. Operational Cost Savings

Low maintenance and long service life reduce downtime and part replacements.

Customizable flow rates and pressure ratings minimize energy loss and ensure cost-effective operation.

• Oil & Gas

Ideal for startup debris filtration and protecting sensitive hardware on offshore platforms, refineries, and pipeline systems.

• Chemical & Petrochemical

Prevents particulate ingress in pumps, valves, and reactors, ensuring process integrity.

• Water Treatment & Marine

Removes sand, grit, and particulates before delicate filtration stages, reducing downtime and maintenance.

• Food & Beverage and Pharmaceutical

Stainless models in sanitary designs are common for high-purity production lines.

• General Industry

Used in hydraulic systems, pump suction lines, and temporary commissioning setups across power plants, manufacturing, and pulp processing.

• Desalination pipeline commissioning application

| Attribute | Details |

| Materials | Stainless Steel 304, 316, 316L; alloy steel; carbon steel; optional titanium and aluminum |

| Mesh and Perforation | Wire mesh (10-500 µm), perforated plates (1-6 mm) |

| Flow & Pressure | Suitable for high-volume, high-pressure systems (150-2500 PSI) |

| Sizes & Ends | Up to Ø48″; flange, butt-weld, socket-weld; inlet and outlet direction customizable(Click here to learn: Witches Hat Strainer Flow Direction) |

| Mesh Levels | Coarse to fine; select according to particle size and application. |

✔ Temporary cone strainers are indispensable during startup, commissioning, or maintenance, allowing quick installation and removal.

✔ Permanent cone filters are built for ongoing service, offering higher structural integrity, and are often welded or flanged into the piping system.

Define your goal: Temporary vs. permanent, coarse vs. fine.

Assess fluid & particles: Check for corrosion, temperature, and particle size. Match flow and pressure needs.

Select material and mesh: Stainless 316 for corrosive or sanitized sectors; alloy for specialized environments.

Plan installation: Ensure compatible connections and easy access for maintenance.

Want help specifying the perfect cone strainer for your application, or sourcing stainless steel models with precise mesh and pressure specs? Get in touch for expert advice and a tailored quote.