Desalination plants are the backbone of modern water supply systems in coastal and arid regions. However, operating in aggressive saltwater environments presents a major challenge — corrosion. Continuous exposure to seawater, high salinity, and biological activity can quickly damage standard filtration components.

That's why wedge wire screens have become the preferred solution for desalination intake and pretreatment systems, offering durability, precision filtration, and outstanding corrosion resistance.

Saltwater is highly corrosive due to its chloride content and electrochemical reactivity. When filtration materials such as carbon steel or inferior alloys come into contact with seawater, they undergo pitting corrosion, crevice corrosion, and stress cracking.

In desalination intake systems, this leads to:

• Reduced filtration efficiency

• Frequent screen replacement

• Costly downtime and maintenance

• Contamination risks in the treatment process

1. Superior Corrosion Resistance

Wedge wire screens are manufactured using marine-grade stainless steels such as 316L, Duplex 2205, and Super Duplex 2507. These alloys contain high levels of chromium, molybdenum, and nitrogen, which form a stable oxide layer that prevents chloride attack.

Result: Long service life and minimal corrosion, even under continuous seawater exposure.

2. Precision Slot Design for Reliable Filtration

Each wedge wire screen is constructed with V-shaped (triangular) profile wires and precise slot openings, ensuring efficient particle separation.

This design minimizes clogging, maintains consistent flow, and supports pretreatment stages such as reverse osmosis (RO) and ultrafiltration.

Result: Stable, high-performance filtration with minimal maintenance needs.

3. Self-Cleaning and Anti-Fouling Performance

The smooth, continuous wire surface reduces biofouling and sediment buildup. In many Coanda-type or self-cleaning screen systems, water flow naturally removes debris before it can accumulate.

Result: Lower operating costs and consistent water quality.

4. Strength and Structural Integrity

Unlike perforated plates or mesh filters, wedge wire screens are welded for strength and stability. This construction enables them to withstand high hydraulic pressure and abrasive particles commonly found in seawater intake systems.

Result: Reliable operation even in harsh marine conditions.

5. Sustainability and Longevity

Because wedge wire screens can last for many years without corrosion or deformation, they align perfectly with the sustainability goals of modern desalination plants.

Result: Lower material waste, fewer replacements, and reduced environmental impact.

Wedge wire screens are widely used in:

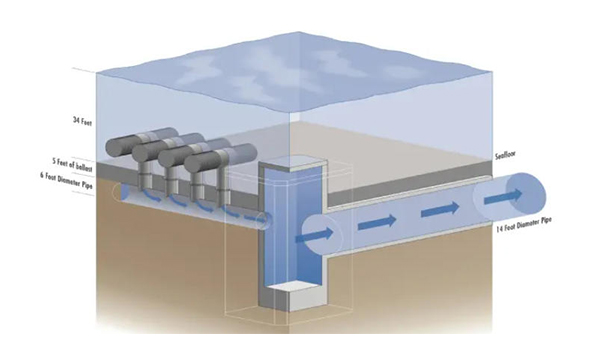

Seawater intake filtration systems

Desalination pretreatment stages (RO and UF systems)

Brine discharge protection screens

Marine water intake for power and process plants

Their versatility and corrosion resistance make them indispensable components in coastal and offshore water treatment infrastructure.

| Material Type | Common Grade | Features |

|---|---|---|

| Austenitic Stainless Steel | 316L | Excellent corrosion resistance in seawater |

| Duplex Stainless Steel | 2205 | Higher strength and pitting resistance |

| Super Duplex | 2507 | Outstanding chloride and crevice corrosion protection |

| Titanium (optional) | Grade 2 | Superior corrosion resistance, lightweight, high cost |

Mesh Filters: Tend to trap particles, leading to clogging and frequent replacement.

Perforated Plates: Offer lower open area and higher pressure drop.

Wedge Wire Screens: Maintain open area, resist corrosion, and deliver precise filtration with low head loss.

In desalination, where uptime and purity are critical, wedge wire technology offers unmatched performance and reliability.

Saltwater corrosion is one of the most persistent challenges in desalination plant design and operation.

By choosing wedge wire screens made from high-grade stainless or duplex steel, engineers can ensure long-lasting filtration performance, minimal maintenance, and sustainable operation.

These screens are more than just filters — they are engineered corrosion solutions that keep desalination systems running efficiently, year after year.

1. Why do desalination screens corrode so quickly?

Seawater contains chloride ions that attack metal surfaces, leading to pitting and crevice corrosion over time.

2. How do wedge wire screens prevent corrosion?

They are made from corrosion-resistant alloys such as 316L or Duplex 2205, which form a protective passive film that blocks chloride attack.

3. Can wedge wire screens handle high-pressure seawater applications?

Yes. Their welded construction and structural strength allow them to perform reliably in high-flow and high-pressure intake systems.

4. What is the lifespan of a wedge wire screen in seawater?

With proper material selection, wedge wire screens can last 10–20 years or more, depending on operating conditions.

5. Are wedge wire screens environmentally friendly?

Yes. They are durable, recyclable, and designed to minimize waste by reducing the need for frequent replacements.