Wedge wire screens are considered self-cleaning due to their V-shaped wire profile, precise slot geometry, and flow-oriented design, which naturally reduce particle lodging, promote continuous solids movement, and minimize surface blinding during operation.

In industrial filtration, self-cleaning does not mean a screen never accumulates solids.

It means:

• Solids are less likely to lodge permanently

• Captured particles are carried away by flow or gravity

• Cleaning frequency and downtime are significantly reduced

Wedge wire screens achieve this through geometry rather than moving parts, chemicals, or backwashing systems.

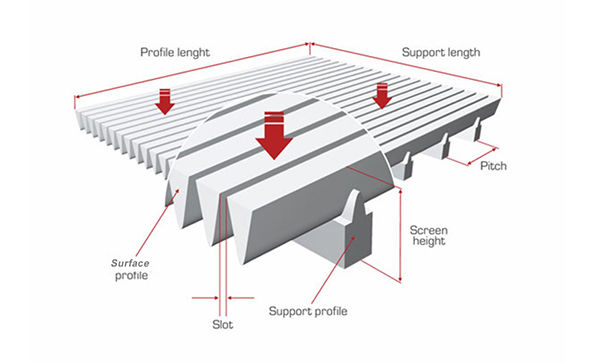

Why the V-Shaped Wire Matters

Unlike round or flat wires, wedge wire screens use a V-shaped (triangular) profile.

This shape creates a critical mechanical advantage:

• The slot opening is narrowest at the surface

• The slot widens internally as depth increases

As particles pass over the surface, they either:

• Pass completely through the slot, or

• Remain on the surface and are swept away

They are far less likely to become wedged inside the slot, which is the primary cause of blinding in traditional screens.

How Slot Shape Supports Self-Cleaning

The slot design of a wedge wire screen follows a simple principle:

Particles should never become tighter as they move through the screen.

In wedge wire construction:

• Slot widths are precisely controlled (often ±0.02 mm)

• Internal slot expansion prevents particle bridging

• Flow velocity increases slightly inside the slot, helping flush fines

This geometry is one of the main reasons wedge wire screens maintain stable performance under high solids loading.

How Hydraulic Design Supports Cleaning

Self-cleaning behavior also depends on how the screen is installed and oriented.

Common design advantages include:

• Cross-flow filtration, where solids move parallel to the screen surface

• Gravity-assisted flow, especially in static and parabolic screens

• Reduced dead zones, where debris would otherwise accumulate

When combined with proper inclination or rotational motion (in drum applications), the screen continuously sheds solids without manual intervention.

| Feature | Wedge Wire Screen | Wire Mesh Screen |

|---|---|---|

| Slot shape | V-shaped, widening inward | Uniform or narrowing |

| Clogging tendency | Low | High |

| Particle lodging | Rare | Common |

| Cleaning frequency | Infrequent | Frequent |

| Structural strength | High | Moderate |

| Service life | Long | Shorter |

The difference lies not in material alone, but in functional geometry.

Most wedge wire screens are manufactured from stainless steel, commonly 304 or 316L.

Material advantages include:

• Smooth surface finish that reduces adhesion

• High corrosion resistance in aggressive media

• Structural rigidity that maintains slot accuracy over time

Maintaining slot integrity is essential. Deformed or worn slots reduce the self-cleaning effect and increase fouling risk.

Wedge wire screens are widely used in applications where continuous operation and low maintenance are critical, such as:

• Water intake and cooling water systems

• Wastewater treatment plants

• Mining and mineral processing

• Food and beverage processing

• Chemical and petrochemical filtration

In these environments, reduced clogging directly translates to lower operating costs and improved system reliability.

Common Questions About Self-Cleaning Wedge Wire Screens

1. Are wedge wire screens completely maintenance-free?

No. While they significantly reduce fouling, periodic inspection and cleaning may still be required depending on solids load and operating conditions.

2. Does slot size affect self-cleaning performance?

Yes. Oversized slots reduce filtration efficiency, while undersized slots may increase surface loading. Proper slot selection is essential for optimal self-cleaning behavior.

3. Can wedge wire screens self-clean in low-flow systems?

Self-cleaning performance improves with adequate flow velocity. In very low-flow systems, supplemental cleaning methods may be required.

The true value of a self-cleaning wedge wire screen is not just reduced clogging. It is:

• More stable filtration efficiency

• Less unplanned downtime

• Lower lifecycle maintenance costs

• Longer service intervals

These benefits make wedge wire screens a preferred choice for engineers designing systems that must operate reliably over many years.

Wedge wire screens are self-cleaning by design because their V-shaped wire profile, expanding slot geometry, and flow-oriented installation work together to prevent particle lodging and surface blinding. This design-driven advantage explains why they outperform traditional screen types in demanding industrial filtration applications.

If you are evaluating filtration solutions where clogging, downtime, or maintenance costs are concerns, understanding this design principle is essential.