Intake screens in industrial water systems clog too fast primarily due to biological fouling, suspended solids, debris accumulation, and poor screen design. High approach velocity, low open area, and non–self-cleaning structures accelerate blockage, increase pressure drop, and shorten service life. Proper screen geometry, hydraulic design, and self-cleaning principles significantly reduce the frequency of clogging.

Intake screens protect pumps, heat exchangers, and downstream filtration systems by removing debris and solids from raw water. When intake screens clog frequently, plants face reduced flow, higher energy consumption, and increased maintenance costs.

Fast clogging is rarely caused by water quality alone. In most cases, it results from a combination of fouling mechanisms, hydraulic conditions, and screen design limitations.

1. Biological Fouling

Biological growth is one of the most common causes of intake screen blockage, especially in surface water sources.

Typical contributors include:

• Algae growth

• Zebra mussels and barnacles

• Microbial slime layers

• Accumulated organic matter

Once biological fouling begins, it traps additional debris and fine solids, accelerating blockage.

2. Suspended Solids and Sediment

Raw water often contains sand, silt, and fine particles. Screens with small openings or low open area allow these solids to lodge in the slots, gradually reducing flow capacity and increasing head loss.

This issue is common in cooling water intake screens that operate continuously.

3. Debris Accumulation

Leaves, sticks, and floating debris can quickly block flat or mesh intake screens. These materials tend to rest on the screen surface instead of being carried away by the flow, leading to sudden blockage events.

4. Poor Intake Screen Design

Many clogging problems originate from design choices rather than operating conditions.

Common design-related issues include:

• Low open area screens

• Incorrect slot size selection

• Mesh or perforated plate designs

• Flat screens without self-cleaning geometry

These designs collect fouling instead of shedding it.

5. High Approach Velocity

Excessive approach velocity forces debris and biological material against the screen surface. This increases impingement, accelerates fouling, and raises differential pressure across the intake screen.

Lower approach velocity significantly slows clogging.

• Mesh screens trap fine solids and organic matter

• Perforated plates clog progressively and have limited open area

• Flat panel screens allow debris to settle on the surface

These designs rely heavily on manual or mechanical cleaning rather than hydraulic self-cleaning.

Rapid intake screen clogging leads to:

• Increased pressure drop

• Reduced pump efficiency

• Higher energy consumption

• Frequent maintenance and downtime

• Risk of pump damage due to insufficient flow

Over time, these issues increase operating costs and reduce system reliability.

Effective clogging prevention focuses on design, not frequent cleaning.

Key principles include:

• High open area to reduce approach velocity

• Proper slot size matched to water quality

• Screen geometry that promotes debris shedding

• Passive self-cleaning hydraulic behavior

Matching the intake screen design to the specific water source is critical.

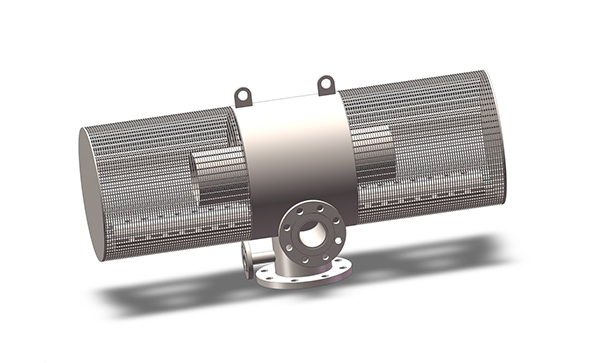

Based on common clogging mechanisms observed in industrial water systems, YUBO expert recommends wedge wire intake screens for applications where frequent fouling and maintenance are persistent issues.

Wedge wire intake screens are designed with V-shaped wire profiles and high open area, which allow water to pass through while minimizing particle impingement. Unlike mesh or perforated plate screens, the slot geometry promotes debris shedding rather than debris retention, reducing the likelihood of rapid blockage.

Key advantages in clogging prevention include:

• Higher open area that lowers approach velocity

• Slot openings that widen inward, reducing particle lodging

• Smooth, continuous screening surfaces that limit biological attachment

• Passive self-cleaning behavior without moving parts

These characteristics make wedge wire intake screens particularly effective in cooling water, seawater, river water, and industrial raw water intake systems where long-term reliability and reduced maintenance are critical.

1. Why do intake screens clog faster in warm seasons?

Higher biological activity and algae growth increase fouling rates.

2. Does a smaller slot size prevent clogging?

No. Smaller slots often increase clogging by trapping fine solids.

3. Can clogged intake screens damage pumps?

Yes. Restricted flow can cause cavitation and premature pump failure.

Intake screens clog too fast when fouling mechanisms, hydraulic conditions, and screen design are not properly aligned. Biological growth, debris loading, suspended solids, and high approach velocity are the primary drivers of blockage.

Selecting intake screens with appropriate open area, slot geometry, and self-cleaning principles reduces clogging, lowers maintenance demand, and improves long-term system reliability.