https://www.yubofilter.com/news/industrial-filter-cartridges.htmlThe cylindrical stainless steel cartridge is a type of filter element. Made of stainless steel as raw material and sintered as the core process.

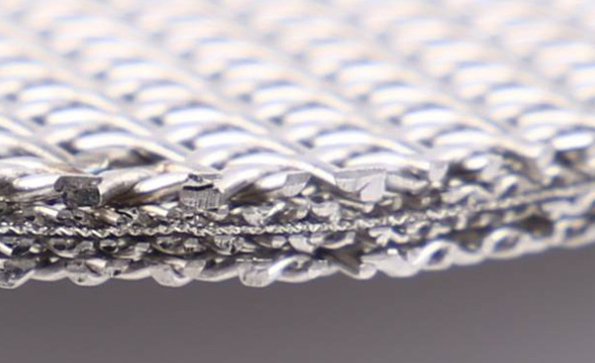

1. Structure: 5 - 7 layers of woven or perforated stainless steel wire mesh overlapped.

2. Process: Vacuum sintering technology.

A cylindrical sintered stainless steel cartridge is a type of filter element constructed using sintering technology, where multiple layers of stainless steel mesh are bonded under high heat and pressure.

This process forms a porous stainless steel cartridge with uniform pore size and superior mechanical strength. The result is a reusable, backflushable, and corrosion-resistant filtration element capable of handling high temperatures and pressures.

• High Temperature and Pressure Resistance

Ideal for high-pressure filtration and elevated temperatures, these cartridges maintain structural integrity even under extreme conditions.

• Corrosion and Chemical Resistance

Made from premium stainless steel, they resist corrosion from aggressive chemicals, acids, and alkalis, making them perfect for chemical processing and petrochemical filtration.

• Uniform Pore Distribution

The multi-layer sintered mesh structure ensures consistent filtration efficiency and reliable contaminant removal.

• Washable and Reusable

Unlike disposable filter cartridges, these sintered units are backflushable, significantly lowering maintenance costs and environmental impact.

• High Dirt Holding Capacity

The depth structure and high porosity increase the cartridge's ability to trap and retain particles, enhancing filtration life.

1. Structure: 5 - 7 layers of woven or perforated stainless steel wire mesh overlapped.

2. Process: Vacuum sintering technology.

| Mesh/Inch | Wire Diameter(mm) | Screen Thickness(mm) |

| 105 | 0.075 | 0.14 |

| 120 | 0.08 | 0.15 |

| 150 | 0.06 | 0.115 |

| 165 | 0.05 | 0.095 |

| 180 | 0.045 | 0.085 |

| 200 | 0.04 | 0.1 |

| 230 | 0.036 | 0.085 |

| 250 | 0.036 | 0.088 |

| 270 | 0.035 | 0.083 |

| 300 | 0.03 | 0.07 |

| 325 | 0.028 | 0.065 |

| 350 | 0.03 | 0.06 |

| 400 | 0.023 | 0.040 |

| 450 | 0.023 |

0.042 |

The sintered stainless steel filter cartridge is widely used across various industries due to its adaptability and robust design:

• Oil and Gas Filtration

Efficient in removing solid contaminants from fuels, lubricants, and hydraulic fluids.

• Water Treatment Systems

Suitable for industrial water filtration, including pre-treatment and post-treatment stages.

• Pharmaceutical and Food Processing

Meets hygienic standards with its welded seamless design and resistance to thermal and chemical stress.

• Compressed Air and Gas Filtration

Used in high-purity gas systems, offering high dirt retention and low pressure drop.

• Catalyst Recovery and Powder Separation

Helps in precise particle capture and recovery processes in reactors and separators.

Custom Solutions Available

We offer a range of custom cylindrical sintered metal filter solutions tailored to your process specifications. Choose from different stainless steel grades, pore sizes, lengths, and end connections to suit your system’s requirements.

Our products are manufactured with strict quality control and advanced sintering techniques. Each cylindrical metal filter cartridge delivers superior performance, long service life, and reliable filtration under harsh conditions.

When precision, safety, and efficiency are non-negotiable, trust in a stainless steel filter cartridge engineered for excellence.

Contact us today to discuss your application and get expert guidance on selecting the right sintered stainless steel cartridge.