Stainless Steel Water Nozzle - Reliable Solution for Liquid, Gas, and Ion Exchange Filtration

YUBO filter nozzles prevent the loss of filter media (such as sand, catalyst, ion exchange resin, silicate, and activated carbon). Features:

1. Large flow area

2. Free from the influence of temperature

3. Corrosion resistance

4. Anti-aging and long service life

The stainless steel water nozzle is primarily used for separating liquids and solids, or gases and solids, to prevent the loss of filter media (such as sand, catalyst, resin, silicate, activated carbon, etc.). It is usually used as a collector and distributor for desalination devices, water softeners, and pressure and gravity sand filters. In the process of liquid or gas collection or distribution, the number and distribution of water caps are designed to achieve a specific flow rate.

In ion exchange systems, stainless steel nozzles ensure that the resin beads remain securely retained while allowing treated water to pass through with minimal pressure drop. This prevents resin leakage, extends system service life, and guarantees consistent water quality in industrial and municipal treatment processes.

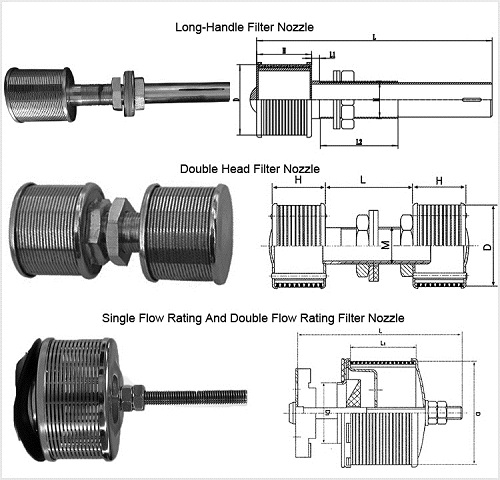

The water nozzle consists of a pedestal, a cover plate, a trapezoidal screen with ribs and a diversion tube. The central axis of the trapezoidal screen is provided with a flow-through valve cup that is inverted and fixed to the pedestal. The lower opening contains the part of the flow-guide tube that extends into the pedestal. The bottom, wall and flow-guide tube of the flow-through valve cup are contained. The upper pipe wall is provided with a plurality of pores, and a flow-through valve core that can float up and down is provided on the top of the draft tube. By setting the flow rate of the trapezoidal screen, the number of round holes, the size of the pore size and the gap distance, the water cap can meet the various flow rate ratios of the backwash and filtered water flow rates under different process conditions.

Materials

To meet the demands of different industries, nozzles are manufactured in corrosion- and wear-resistant materials:

AISI 304, 304L

AISI 316, 316L

SS 904L

Super Duplex 2507

Hastelloy and other special alloys

These alloys offer superior resistance to chlorides, chemical agents, and high operating pressures, making them suitable for use in power plants, petrochemical processes, and ion exchange water treatment systems.

• Large flow area: supporting high-capacity filtration and backwash efficiency

• Temperature resistance: stable performance under varying conditions

• Outstanding corrosion resistance: suitable for seawater, brine, and chemical solutions

• Anti-aging and long service life: reducing replacement frequency and maintenance costs

• Easy replacement: modular design simplifies installation and servicing

• Safe and reliable: protecting filter media and ensuring process consistency

Applications

The stainless steel water nozzle is a versatile solution widely adopted across industries:

• Ion Exchange Filters

Ion exchange filters are at the core of many water treatment and purification processes, including demineralization, softening, and condensate polishing. The performance of these systems depends on effective resin retention and uniform flow distribution.

✔ Retains resin beads while allowing treated water to pass

✔ Provides uniform distribution for efficient regeneration

✔ Prevents resin leakage, ensuring consistent demineralization or softening performance

• Power Plants: cooling water pre-treatment and condensate polishing

• Petrochemical & Chemical Industries: filtration of catalysts, solvents, and process fluids

• Pharmaceutical & Food Processing: hygienic liquid-solid separation with strict safety compliance

• Beverage Industry: ensuring clean, safe, and pure water for production

We are a professional supplier and manufacturer of stainless steel filter nozzles for liquid, gas, and ion exchange filtration. OEM and custom design service, nice price.