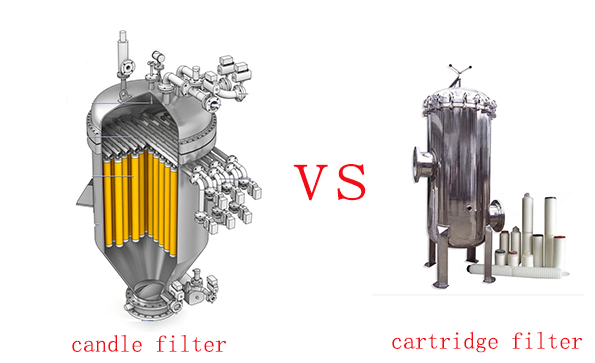

Candle filters and cartridge filters are two common liquid filtration solutions in industries. Choosing the right filter type ensures optimal performance, longevity, and cost-effectiveness.

Candle filters, tubular filters, are cylindrical filtration units consisting of a housing filled with multiple filter elements (candles). These candles are typically made from stainless steel, polypropylene, or ceramic.

The liquid to be filtered flows through the element, and the impurities are trapped inside the filter, while the clean liquid passes through.

| Advantages of Candle Filters | Limitations of Candle Filters |

High Dirt Holding Capacity Strong Durability and Long Service Life Backwashing Capability Versatility and Suitable for Various Industries | Size and Space Requirements More Lager More High Initial Cost |

Cartridge filters are cylindrical filtration units a replaceable filter element (cartridge) housed within a casing. These cartridges are usually made from cellulose, polypropylene, or polyester, and are designed for specific filtration ratings.

Click here to learn about: What Does Cartridge Filter Remove?

| Advantages of Cartridge Filters | Limitations of Cartridge Filters |

High Filtration Precision Compact Design, suitable for installations with limited space. Ease of Replacement Cost-Effective, More Low Initial Cost | Lower Dirt Holding Capacity Single-Use Nature Limited Durability, Frequent Replacements |

▪ Application Requirements

High Contaminant Load: If your application involves a high level of particulate matter, a candle filter's high dirt-holding capacity and backwashing capability make it a better choice.

Precision Filtration: For applications requiring highly precise filtration, such as pharmaceutical or semiconductor industries, cartridge filters offer a wide range of filtration ratings to meet stringent requirements.

▪ Space and Installation Constraints

Limited Space: If installation space is a concern, the compact design of cartridge filters makes them a more viable option.

Durability Needs: For applications requiring robust and durable filtration solutions, candle filters are often the better choice due to their sturdy construction.

▪ Cost Considerations

Initial Investment vs. Operational Costs: While candle filters may have a higher initial cost, their longer lifespan and lower maintenance needs can offer cost savings in the long run. Conversely, cartridge filters have a lower initial cost but may require more frequent replacements, leading to higher operational costs.

Click here to learn about Bag Filter vs. Cartridge Filter

Candle filters and cartridge filters offer unique advantages and are suitable for different applications. Understanding your specific filtration requirements, space constraints, and budget will help you choose the right solution.