Cartridge filters provide a cost-effective and efficient way to remove contaminants from liquids and gases. Their modular design and easy installation make them suitable for applications ranging from water treatment to industrial processes.

The cartridge filter is a tubular filtration device that houses a cylindrical filter media. This filter media can consist of stainless steel, polyester, polypropylene, cellulose, or carbon. It traps contaminants as fluids or air passes through.

Click here to learn about: Candle Filter vs Cartridge Filter

There are different types of cartridge filters, each designed to remove specific contaminants. The most common types are:

▪ Sediment Filters – Focus on removing large particles and debris.

▪ Carbon Filters – Primarily remove chlorine, odors, and organic compounds.

▪ Pleated Filters – Designed for a higher surface area, catching smaller particulates.

▪ Depth Filters – Trap contaminants throughout the thickness of the filter material.

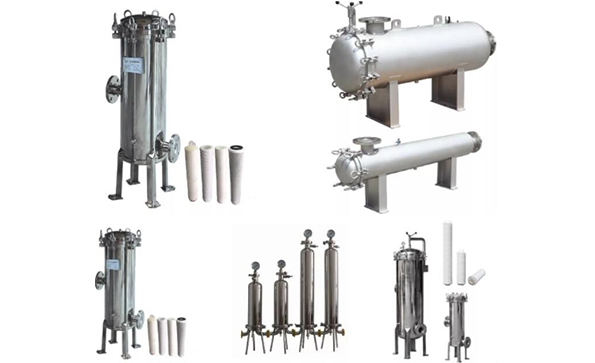

We can provide various cartridge filters for liquid and gas filtration.

1. Sediment and Particulates

One of the most common uses for cartridge filters is the removal of sediment and particulates. It includes dust, sand, dirt, silt, and rust particles in liquids or gases. These solid contaminants can clog pipes, damage equipment, or affect the quality of end products. Cartridge filters with varying levels of pore sizes (micron ratings) can trap these particles effectively.

Common applications: Drinking water systems, industrial water treatment, and HVAC systems.

2. Chlorine and Chemical Compounds

Cartridge filters, particularly those made with activated carbon, are excellent at removing chlorine and other chemical contaminants from water. Activated carbon works by adsorbing chemicals, which means they are attracted to and held on the surface of the carbon granules. Chlorine, often present in municipal water supplies, can affect the taste, smell, and safety of water.

Common applications: Residential water filtration systems, commercial kitchens, and beverage manufacturing.

3. Organic Contaminants

Organic materials like algae, bacteria, and viruses can also be removed by specific types of cartridge filters, especially those that contain activated carbon or are designed for microbiological filtration. In some cases, additional treatments, such as UV sterilization, are paired with cartridge filters to enhance microbial removal.

Common applications: Food and beverage production, aquaculture, and healthcare facilities.

4. Heavy Metals

Certain cartridge filters can also remove heavy metals such as lead, copper, and mercury from liquids, particularly in water filtration. Filters that contain specialized media can adsorb or chemically bind these metals, preventing them from contaminating water supplies.

Common applications: Drinking water systems, industrial wastewater treatment, and environmental remediation.

5. Oils and Greases

Cartridge filters can remove oils, greases, and other hydrocarbons from liquids in industrial applications. Filters made from materials like polypropylene are especially effective at capturing oily residues and emulsified oils, which can be harmful if released into the environment.

Common applications: Automotive industry, oil and gas, and chemical manufacturing.

6. Dissolved Solids

Cartridge filters can be part of a multi-stage process to remove dissolved solids in desalination or ultrapure water production applications. While not designed to remove dissolved ions or minerals independently, they often precede or follow reverse osmosis systems to enhance overall filtration.

Common applications: Semiconductor manufacturing, pharmaceutical production, and laboratory research.

7. Odor and Taste

Cartridge filters, particularly carbon-based filters, can also remove unpleasant odors and tastes from water and other liquids. These filters adsorb the organic compounds responsible for bad smells and tastes, making them ideal for improving the sensory quality of water and beverages.

Common applications: Residential water filtration, coffee brewing, and beverage production.

Cartridge filters are highly versatile and essential in many industries. They can remove various contaminants, including sediment, chemicals, microorganisms, heavy metals, and more.

If you need a reliable cartridge filter system, consult with a filtration specialist to determine which cartridge filter is best suited for your application!