Designing an industrial filtration system is not only about selecting filter media. For OEMs and system integrators, the choice of filtration internals, nozzles, laterals, or support grids directly determines flow distribution, pressure drop, media retention, and long-term reliability.

In pressure vessels, filters, reactors, and ion exchange units, filtration internals perform three critical functions:

• Uniform flow distribution across the bed or filter media

• Secure media retention without excessive pressure loss

• Mechanical support under operating and backwash loads

Poor selection can lead to channeling, resin loss, uneven backwashing, premature fouling, or structural failure. OEMs must therefore evaluate internals as engineered components, not accessories.

1. Filtration Nozzles

2. Lateral Collector Systems

3. Support Grids and Support Plates

Each option serves a different combination of flow rate, vessel size, media type, and load requirement.

| Performance Comparison | Screen Nozzle | Wedge Wire Lateral System | Support Grid |

| Overview | Filtration nozzles are discrete flow distribution and retention elements mounted on underdrain plates or headers. | Lateral systems use radial or parallel collector pipes connected to a central hub to distribute or collect flow. | Support grids are load-bearing structures designed to support filter media, catalyst beds, or adsorbents. |

| Key Characteristics | Available in slotted, wedge wire, or Vee wire designs Typically made from stainless steel or engineered polymers Installed in large quantities for uniform flow | Slotted or wedge wire laterals Hub-and-lateral or radial lateral configurations Common in pressure vessels | Wedge wire or perforated plate construction High mechanical strength Designed for static and dynamic loads |

| Where Perform Best | Ion exchange columns Water treatment filters Resin traps and polishing filters Systems requiring precise media retention | Large-diameter vessels High-flow filtration systems Ion exchange and multimedia filters | Reactor vessels Catalyst beds High-temperature or high-pressure applications |

| Advantages | Excellent flow uniformity Strong anti-clogging performance with wedge wire designs Easy replacement and modularity | Efficient coverage of large vessel areas Lower component count than nozzle systems Good balance between flow and cost | Exceptional mechanical stability Minimal deflection under heavy loads Long service life in harsh conditions |

| Limitations | Installation density increases cost in large vessels Structural support is limited compared to grids | Less precise flow distribution than dense nozzle layouts Replacement can be more complex | Not optimized for fine flow distribution alone Often paired with screens or secondary internals |

Key Design Questions OEMs Should Ask

1. What is the vessel diameter and flow rate?

Small to medium vessels → Nozzles

Large vessels with high flow → Laterals

Heavy beds or catalysts → Support grids

2. What media must be retained?

Fine resin or sand → Wedge wire nozzles or laterals

Large catalyst pellets → Support grids

3. Is backwashing required?

Frequent backwash → Nozzles or laterals with uniform distribution

Static beds → Support grids

4. What are the mechanical load requirements?

Low load → Nozzles or laterals

High load → Support grids

| Application | Recommended Internals |

|---|---|

| Ion exchange systems | Wedge wire nozzles or laterals |

| Water treatment filters | Filter nozzles |

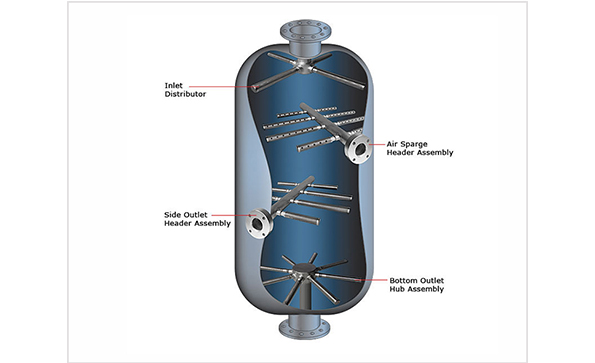

| Large pressure vessels | Hub and lateral systems |

| Chemical reactors | Support grids |

| Catalyst beds | Wedge wire support grids |

OEM filtration internals are commonly manufactured from:

• Stainless steel 304 and 316L

• Duplex stainless steel

• Custom wedge wire profiles

Precision slot control, corrosion resistance, and weld integrity directly affect performance and service life.

• Design internals as part of the system, not after the vessel

• Match slot size to media with adequate safety margin

• Balance pressure drop with flow uniformity

• Validate designs with operating and backwash conditions

• Work with manufacturers experienced in custom OEM fabrication

We are a professional and experienced custom OEM wedge wire screen manufacturer, including wedge wire filter nozzles, hub and header laterals, resin traps, and support bed grids.

Choosing between nozzles, laterals, and support grids is a fundamental decision in OEM filtration design. The correct choice improves efficiency, protects process media, reduces maintenance, and extends system life.

By evaluating flow requirements, vessel geometry, media characteristics, and mechanical loads, OEMs can engineer filtration systems that perform reliably across their full operating cycle—meeting both process and commercial expectations.

1. What is the main difference between nozzles and laterals?

Nozzles provide highly uniform local flow control, while laterals distribute flow over larger areas with fewer components.

2. When is a support grid necessary?

Support grids are required when the media or catalyst bed imposes a significant mechanical load that nozzles or laterals cannot carry.

3. Can these systems be combined?

Yes. Many OEM designs use support grids with wedge wire screens or nozzles to balance strength and flow distribution.

4. Are wedge wire internals better than perforated plates?

For most filtration applications, wedge wire offers better anti-clogging performance and slot precision.