Water treatment plants operate under constant pressure to maintain uninterrupted flow, consistent water quality, and strict regulatory compliance. One of the most persistent operational challenges is unplanned downtime, often caused by clogged intake screens, high-solids loading, and frequent manual cleaning.

Self-cleaning wedge wire screens have emerged as a proven solution that prevents these issues and stabilizes plant performance.

Unplanned shutdowns in water treatment plants typically trace back to:

• Clogged intake screens caused by algae, leaves, plastics, grit, or biofilm

• High-solids spikes during storms or industrial discharge

• Manual cleaning frequency, which interrupts normal system operations

• Corrosion or screen fatigue, especially in older metal mesh screens

• Pump overloads due to restricted flow

According to industry field data, screen blockages account for 25–35% of unexpected plant stoppages in municipal and industrial water facilities. This makes the screening stage one of the highest-impact points for optimization.

1. Continuous Cleaning Mechanism

Self-cleaning wedge wire screens utilize backwashing, rotating drums, or hydraulic sweeping to automatically remove debris.

This prevents solids from building up—eliminating the downtime associated with manual screen raking.

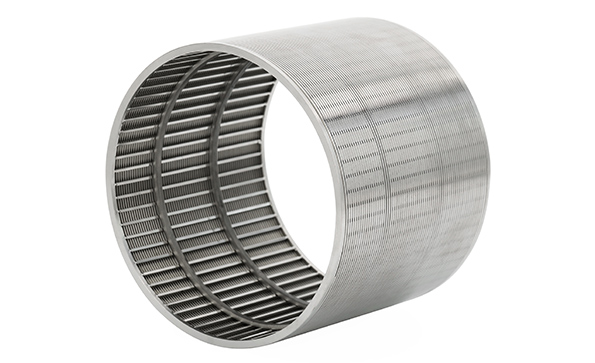

2. Non-Clogging V-Shaped Wire Profile

The wedge wire slot is designed as an inverted V, allowing debris to pass over the surface instead of wedging into the slot.

This geometry provides:

• Up to 30% higher open area than a perforated plate

• More stable flow under variable solids loading

• Resistance to fibrous clogging

3. Higher Throughput and Stable Flow Rates

A typical stainless steel wedge wire screen retains:

• 90–95% of its hydraulic capacity even under heavy solids

• 50–70% longer operating cycles compared with traditional mesh screens

These performance characteristics directly translate to fewer flow disruptions.

4. Corrosion-Resistant Stainless Steel Construction

Most self-cleaning wedge wire screens are built from 304, 316, or 316L stainless steel, providing:

• Long service life

• Minimal structural degradation

• Consistent slot accuracy

This structural reliability reduces equipment failures and unscheduled maintenance.

5. Reduced Manual Labor and Maintenance Costs

Plants using self-cleaning systems typically report:

• 40–60% reduction in manual cleaning hours

• 20–30% lower maintenance costs

Significant increases in uptime during seasonal debris spikes

Self-cleaning wedge wire screens are especially effective in:

• Municipal wastewater treatment (primary screening, pretreatment)

• Industrial wastewater treatment

• Surface water and river intake systems

• Cooling water intake

• Desalination pretreatment systems

• Food processing, pulp & paper, and textile wastewater

Any facility dealing with variable solids loading or persistent clogging benefits from the technology.

Reducing downtime in water treatment facilities requires equipment built to handle changing solids loads, corrosive environments, and continuous operation.

Self-cleaning wedge wire screens provide a robust, low-maintenance solution that directly enhances plant efficiency, extends equipment lifespan, and stabilizes treatment performance.

Their combination of non-clogging geometry, continuous cleaning, corrosion resistance, and high hydraulic capacity makes them one of the most reliable screening technologies available today.

1. What slot sizes are commonly used for high-uptime water treatment applications?

Typical slot widths range from 0.25 mm to 2.0 mm, depending on influent quality, hydraulic capacity, and downstream equipment specifications. Narrower slots are used for fine screening, while wider slots support higher flow and lower headloss.

2. How long does a stainless steel wedge wire screen typically last in continuous operation?

In municipal and industrial environments, stainless steel 304 and 316L wedge wire screens usually provide 10–20 years of service life, depending on abrasion, chemical exposure, and cleaning frequency. Their structural rigidity allows them to maintain slot accuracy over long operating periods.

3. Are self-cleaning wedge wire screens compatible with existing plant infrastructure?

Yes. Most manufacturers provide retrofit-ready designs that match existing channel widths, drum diameters, or intake housings. Plants can integrate them without major civil modifications, making the upgrade cost-effective.